Optical fiber provides many fundamental advantages over alternative transmission technologies for telecommunications applications. The comparatively limited performance of copper conductor based systems forces the use of expensive signal conditioning and regeneration equipment (e.g., amplifiers and repeaters) at much closer intervals than for fiber optic systems.

A single line of a voice grade copper system (i.e., 56 kbs) longer than a couple of kilometers requires the use of in-line signal processing for satisfactory performance, and even then is subject to the electromagnetic effects of interfering radio frequency sources such as radio, television, cell phone, and air traffic control broadcasts.

As information throughput requirements increase with the demands of more data-intensive applications at the end-user premises, the spacing between the copper-based repeater points must decrease in order to maintain the same aggregate data rate capability over a given length.

Contrast that to all-optical systems in which it is not unusual to transmit 10 gigabits per second data rates over hundreds of kilometers without the need for active signal processing between the transmitter and receiver.

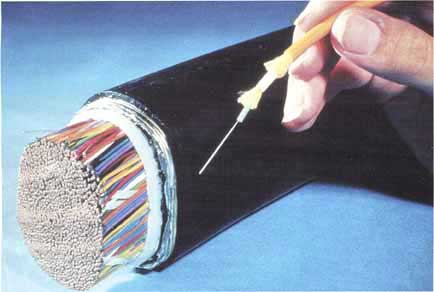

Additionally, as it becomes necessary to increase the data transmission capacity or coverage area of a telecomunications system, the diameter and weight of cables for copper conductor systems increase much more rapidly than for optical fiber systems, resulting in a proportionally higher increase in materials, installation, and maintenance related costs.

The small size of optical cables, coupled with readily available components that make efficient use of the optical fiber’s transmission capabilities, enable them to be manufactured and installed in much longer lengths than copper cables. The virtually unlimited capacity of optical fiber also alleviates fears of incurring significant long-term costs associated with frequent system upgrades, extensions, or over builds.

The availability of long lengths of individual lightweight fiber optic cables, up to 10 km or more, also make the installation of fiber optic systems much safer, easier, and less expensive, than comparable copper-based systems.

Because of their design, fiber optic cables can generally be installed with the same equipment historically used to install twisted pair and coaxial cables, allowing some consideration for the smaller size and lower standard tensile strength properties of fiber optic cable.

More importantly, fiber optic cable design has progressed to the point where it serves as an enabling technology for newer installation methods that are faster, less expensive, and less intrusive to the environment than traditional installation means. Optical cables can be installed in duct system spans of 4000 meters (m) or more depending on the condition, construction, and layout of the duct system, and the details of the installation technique(s) used.

Even longer lengths of fiber optic cable can be installed aerially, trenched, or buried in the ground and ocean floor. These extra-long lengths of cable reduce the number of splice points, thereby making the overall installation of optical fiber based telecommunications systems more efficient. The small size of fiber optic cable also saves on valuable conduit space in buried duct applications.

This feature becomes even more prevalent when considering some emerging cable types that are specifically designed for use with air-blown or air-assist installation techniques into miniature ducts that are only about one centimeter in diameter.

Another advantage of optical fiber and fiber optic cable is the inherent flexibility in design options, allowing for the development of innovative products for specific applications. Since optical fiber is a man-made composite glass structure, it can be custom designed to meet optimal cost/performance targets in any number of specific applications.

As it does not conduct electrical current and is not affected by electromagnetic interference, fiber optic cable can be made all dielectric, making it the ultimate in electromagnetically compatible transmission media.

This eliminates such issues as dangerous ground loops, the effects of voltage spikes from the cycling of heavy electrical equipment, and requirements for separate conduits for metallic conductors.

It also improves the security of controlled transmission rooms as it is much more difficult to tap a fiber optic line, and much easier to provide security for fiber optic cable.